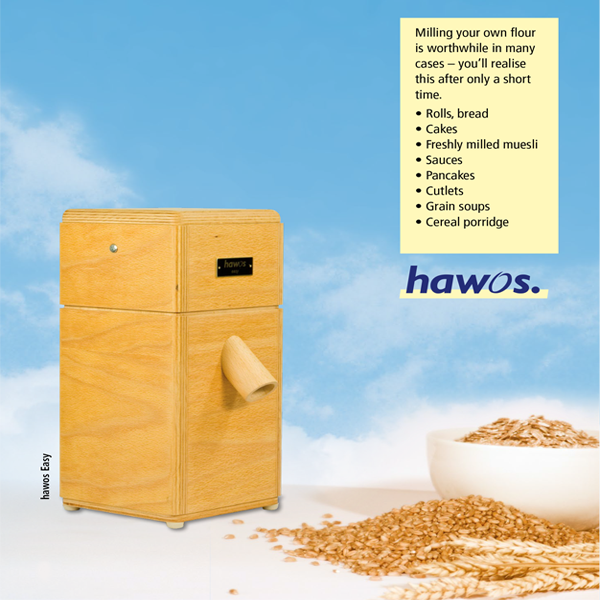

“Hawos Mills” Quality Assurance

Get the best results with your hawos flour mill

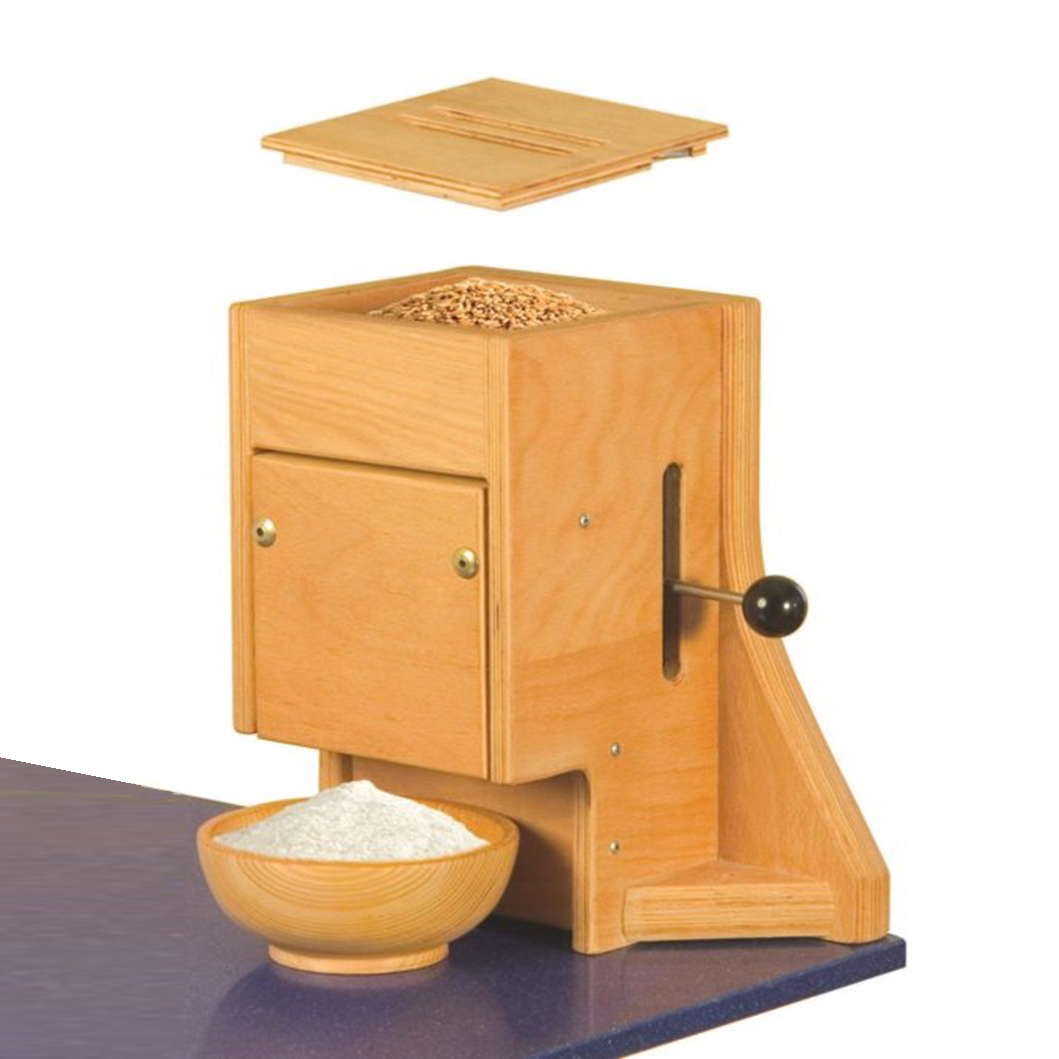

Mills with steel plates or teeth apply cutting and frictional forces, but rarely achieve the fineness that stone-mills can provide. Stone grinders shell the kernels from the outside inwards and then gently grind them. Hawos flour mills use extremely hard grindstones made of compressed, baked corundum ceramic composite. They are resistant to debris and deliver ideal, consistent grinding results.

No mill leaves our premises until it has passed stringent controls

Every single hawos mill undergoes visual, acoustic, mechanical and fineness testing as part of our quality controls.

The grinding chamber is also fine-tuned as part of the final inspection by grinding wheat. For celiac we can fine-tune and test it with gluten free alternatives such as corn so that you get the best results for your usage scenarios.

If at least 90 % of the mill feed passes through a lab sieve with a mesh size of 0.315 mm on the finest setting, the grinding chamber and settings are considered to be fine – only then are we satisfied. Only once the quality tests have been passed, it receives the hawos name badge.